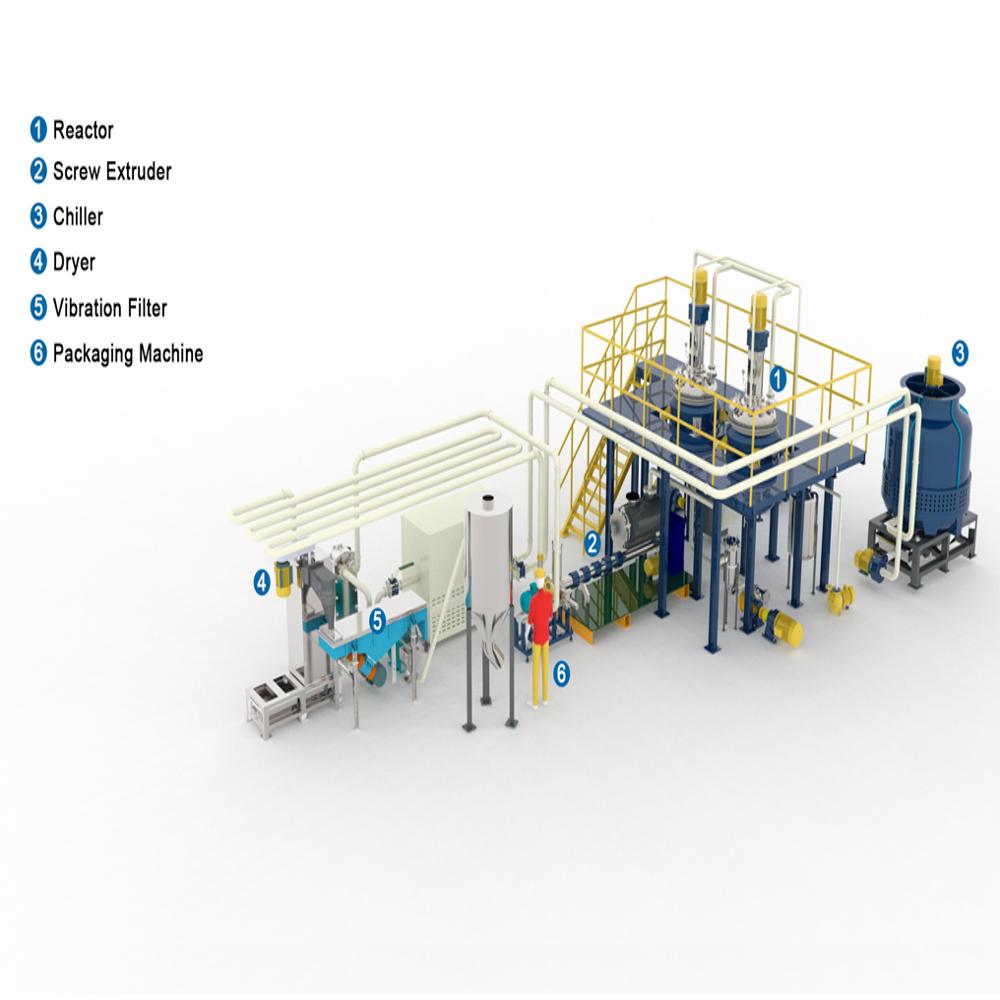

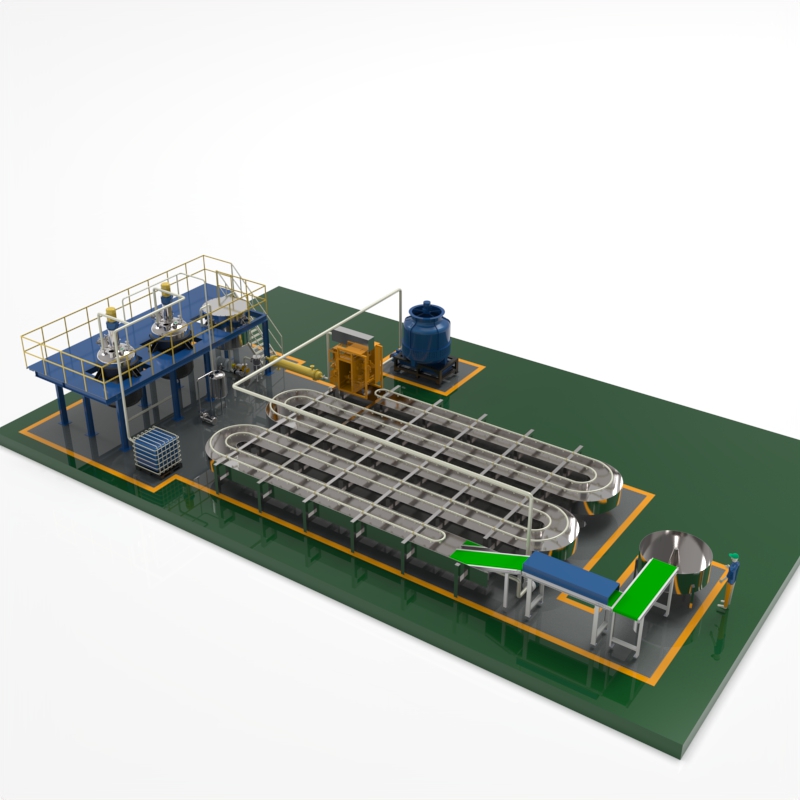

Hot melt adhesive granule production line

Hot melt adhesive granule production line Specification

- Cutting Type

- Strand cutting

- Heating Zones

- Multiple zones

- Extruder Type

- Twin screw extruder

- Feeding Type

- Automatic feeder

- Packaging

- Bagging system

- Cooling Method

- Air cooling

- Hopper Material

- Stainless steel

- Safety System

- Emergency stop

Hot melt adhesive granule production line Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- GuangZhou

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 15 Pieces Per Month

- Delivery Time

- 45 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden box packaging

- Main Export Market(s)

- Asia, Australia, Eastern Europe, Central America, North America, South America, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- CE certification

About Hot melt adhesive granule production line

Our automatic hot melt adhesive production line is a highly efficient and intelligent manufacturing system designed for large-scale, high-precision production of various hot melt adhesives (including EVA, PA, PES, and other types). Featuring fully automated control, modular configuration, and advanced process technology, this production line enables end-to-end automationfrom raw material feeding to finished product packagingsignificantly improving production efficiency and product consistency while reducing labor costs and energy consumption.

Fully Automated Production

- Equipped with a PLC-based control system, enabling unmanned operation for key processes such as melting & mixing, reaction control, cooling & shaping, and cutting & packaging.

High Efficiency & Energy-Saving Design

- Jacketed reactor with high-efficiency heat exchange system improves thermal energy utilization by over 30%.

- Variable frequency drives and intelligent temperature control technology ensure precise adaptation to different adhesive formulations.

Modular & Flexible Configuration

- Customizable capacity (e.g., 500 kg/h to 5 T/h) and adhesive forms (granules, blocks, strips, or pillow-shaped).

- Supports multi-formula switching for various hot melt adhesives (EVA, polyamide, polyester, etc.).

Safety & Environmental Compliance

- Enclosed production process with exhaust gas treatment system, meeting environmental standards.

- Explosion-proof electrical design and emergency stop function, certified with CE compliance.

Price 5500000.0 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 15 Pieces Per Month

- Delivery Time

- 45 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Eastern Europe, Central America, North America, South America, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Melt Adhesive Production Line Category

Industrial-grade reactor hot melt adhesive production line-Features: High efficiency

Price 5500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Pilot Plant Hot Melt Adhesive System-Stainless Steel 304, 415V, High-Torque Motor | Computerized Process Control, Real-Time Viscosity Monitoring

Price 5500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Industrial-grade hot melt adhesive granule production line

Price 5500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Compact Hot Melt Glue Production Line-Ideal for Small to Medium-Scale Manufacturers

Price 8500000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry Call Me Free

Call Me Free